Our Story

Turbo Air Products

We manufacture commercial refrigerators, freezers, and supermarket equipment. Turbo Air provides all your food service equipment needs.

Global Sales

By participating in international exhibitions, we will enter the global market soon.

Fast Warranty Service & Parts Supply

Turbo Air provides fast and efficient services, responding to 95% of customer service requests within 24 hours. This demonstrates our commitment to customer satisfaction and high-quality service.

Frost Air Technology

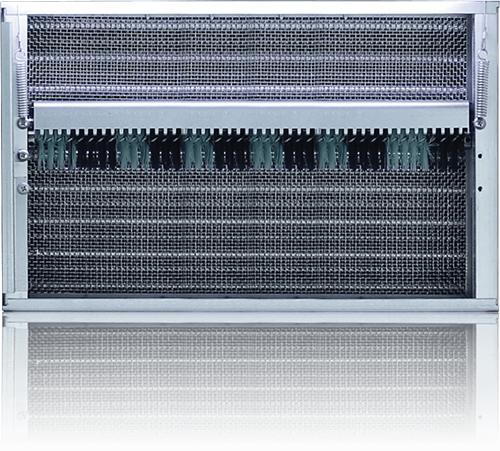

Self-Cleaning Condenser

How It Works

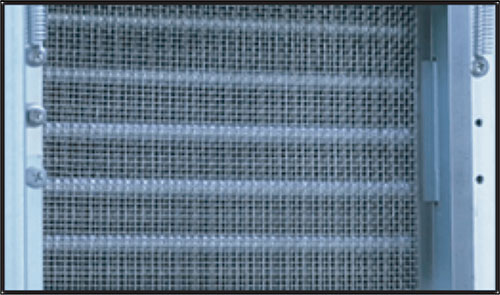

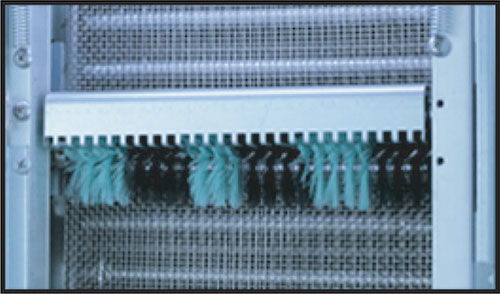

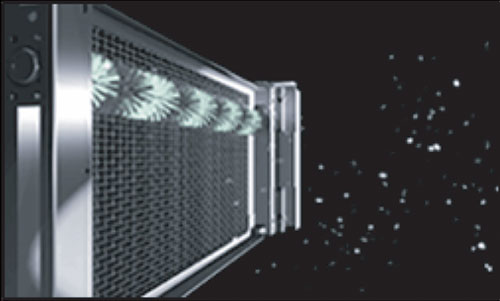

The upcoming self-cleaning condenser is an innovative feature that collects dust using a mesh filter, while a rotating brush moves up and down 2–3 times a day to remove excess dust, preventing accumulation. This allows the system to operate at peak efficiency and avoids premature system failure.

Fine Mesh Filter

Rotating Brush

Prevents Dust Accumulation

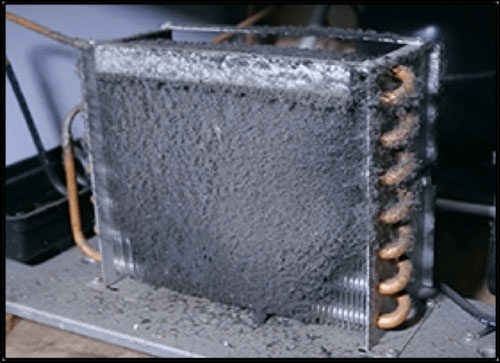

Dirty Condenser

What problems does a dirty condenser cause?

Primary Filter

Dirty Condenser

Heat Issues

High-traffic environments such as markets and restaurant kitchens quickly accumulate dust, causing the condenser to become dirty. If not properly maintained, a dirty condenser can lead to major problems like increased energy consumption, compressor failure, failing health inspections, and voided manufacturer warranties.

Dirty condenser coils are a common service issue in commercial refrigeration systems.

Innovation for Solutions

Patented Standard Feature

The Frost Air self-cleaning condenser is a standard feature. Our customers can enjoy this great option across most of our production lines at no extra cost.

Frost Air’s top priority is our customers. We understand your business. Frost Air will continue to strive to provide better solutions for this industry and, most importantly, for our customers.

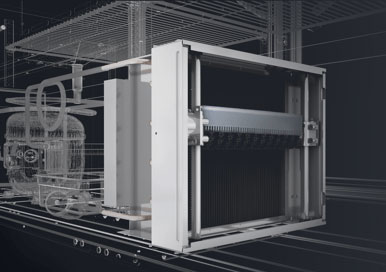

Self-Cleaning Condenser System (Coming Soon)

High-traffic markets generate a lot of dust. The dust is drawn through the fan and accumulates, preventing the condenser from releasing heat properly. This increases compressor pressure and the likelihood of failure. The self-cleaning condenser system uses a rotating brush moving 2-3 times a day to prevent dust accumulation, maintaining maximum efficiency while saving extra energy.

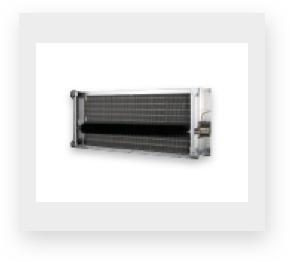

Energy-Saving Fan Controller

Inside the refrigerator, a fan motor runs 24/7 to circulate cold air, generating significant heat. When the compressor is inactive, this heat can increase temperature instead of cooling. Frost Air engineers tirelessly researched and tested a perfect algorithm to stop the fan motor when a temperature rise is detected, saving 15%-25% energy and extending compressor life.

Energy Star Partner

Frost Air will soon begin producing its products with national standard labels and ISO certification.

This achievement represents a major step toward improving quality and gaining customer trust, promising a brighter future for Frost Air products in domestic and international markets.

![]()

Natural Refrigerant

Soon, natural refrigerants will be used in all Frost Air refrigeratorsThe most common refrigerants used in the industry are HFCs (hydrofluorocarbons R-134a, R-404A), which replaced CFCs. These gases are known to be harmful and affect the ozone layer. HFCs do not directly destroy ozone but are strong greenhouse gases, contributing to global warming up to 4000 times more than CO2. High-GWP refrigerants are monitored under the Kyoto Protocol 1992, and HFCs such as R-134a and R-404A have been banned in the US since January 1, 2019.

The industry must adopt natural and eco-friendly hydrocarbon (HC) refrigerants.

What is Hydrocarbon (HC)?

HC (hydrocarbon) is a sustainable replacement for HFCs. Hydrocarbons (R-600A, R-290) are natural refrigerants with zero ozone depletion potential (ODP) and very low global warming potential (GWP). Additionally, hydrocarbon-based equipment is more energy-efficient than HFC-based equipment, reducing operating costs. The US EPA has approved R-290 (propane) and R-600A (isobutane) as acceptable refrigerants for commercial refrigerators, upright refrigeration equipment, and freezers.